- Welcome to OUBEL !

- +86 755 2954 6287

- sales@obsmt.com

The Pros and Cons of Through-Hole Technology

Pneumatic PCB V cutter VS Manual pusher PCB V cutter

September 21, 2019

New design machines developed,weclome to visit our company!

April 10, 2020We recently discussed the benefits and limitations of surface mount technology (SMT), so today we would like to look at the alternative: through-hole technology(THT).

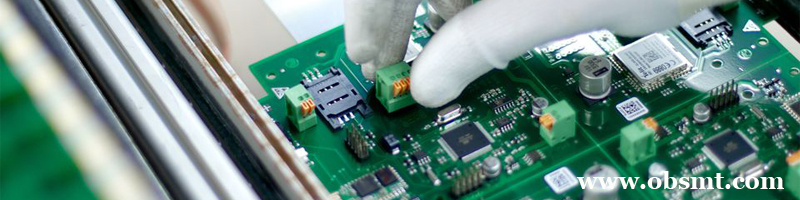

OUBEL-through-hole technology

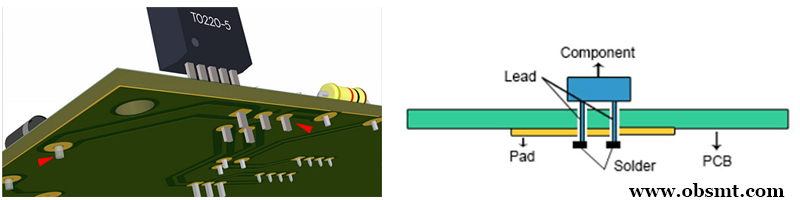

Through-hole is an easy form, with leads threaded through pre-drilled holes forming a criss-cross pattern on the opposite side. The leads are bent into 90-degree angles in opposite directions for mechanical strength, then soldered in place.

OUBEL-through-hole technology

Advantages of Through-Hole Technology:

Despite the rise of surface-mount technology, through-hole has held its own because of its reliability. Through-hole soldering creates a stronger bond between components and the board, making it perfect for larger components that will undergo high power, high voltage, and mechanical stress, including:

A:Transformers

B:Connectors

C:Semi-conductors

D:Electrolytic capacitors

Because components run through the board, they can also withstand more environmental stress. That is why through-hole technology is the preferred method for military and aerospace products that experience extreme accelerations or high temperatures.

Their durability also makes them the best choice for prototyping and testing.

Advantages of Through-Hole Technology

Disadvantages of Through-Hole Technology:

The main disadvantages to THT come from the need to drill multiple holes through the board. This lengthens production time and increases production costs.

The holes, while necessary to secure components in place, also limit available space and routing area for tracing signals.

Disadvantages of Through-Hole Technology

High quality PCB production and assembly machines in China:

Speaking of reliable, professional PCB production and assembly machines, we are a professional SMT&DIP machine manufacturer in China, providing surface mounting and through-hole technology. With fast quotation, fast prototype and fast production delivery, OUBEL is your reliable partner.

OUBEL GROUP