- Welcome to OUBEL !

- +86 755 2954 6287

- sales@obsmt.com

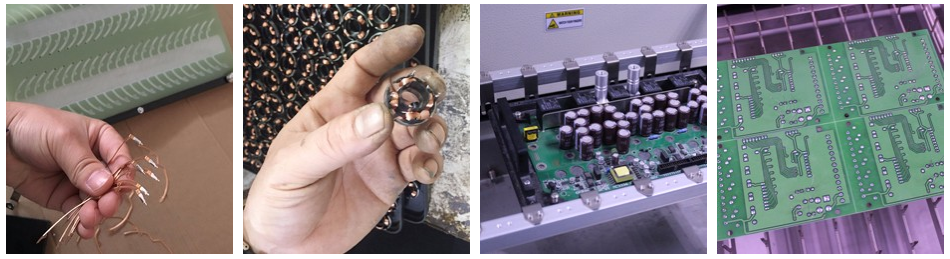

Semi-automatic PCB DIP soldering machine

Shop

Automatic PCB surface cleaner

December 14, 2017

Semi-automatic solder paste printer

December 14, 2017Semi-automatic PCB DIP soldering machine

Model: OB-S310

Brand: OUBEL

Delivery Time: 5-10 working days

Semi-automatic PCB DIP soldering machine is used for dipping the PCB with THT chips. Economic type.

** E: sales@obsmt.com

Semi-automatic PCB DIP soldering machine

Features

1.Up and down running using the step motor driving the ball screw, precision is up to 0.1mm, welding depth is accurate.

2.Up&down speed and the welding angle are adjustable,which decrease the surface tension, fulfill the technique requirement.

3.Automatic clear the solder oxide to the solder splash pot every work cycle,improve the welding quality.

4.Welding time, 1s-10s can be adjustable.

5.Soldering pot applies to the special thicky stainless steel, temperature controller applies to the K-thermocouple.

6.Suitable for the small quantity production.

7. With tri-color light, when over set temp. It will alarm and red light.

Working mode

Power cost ≤ 1degree, 8H Oxide <0.2Kg , No need technique support!

Suitable for LONG/SHORT lead welding !

Production cost is 1/20 than the normal wave soldering machine . It’s the 1/10 cost of energy saving wave soldering. It can also weld different batches of products at the same time.

No PCB edge also suitable ! No Wastage!

Solder capacity: 80KGS

Specifications

| Model | OB-S310 |

| Dimensions | 820mm*700mm*1180mm |

| Pot size | 450mm*350mm*80mm |

| Pot capacity | 80KGs |

| Solder Residue Capacity in 24 hours | 0.2KG-1.0KG(the specific should according to the production and the quality of the solder) |

| Power | 220V/50Hz-60Hz |

| Initial power | 4500W |

| Constant temperature power | 800W-1200W |

| Start control method | Manual control or foot switch control |

| Heat-up time | approx. 50 minutes |

| Temperature control | PID+SSR driving, precision is ±3℃ |

| power | 1P AC 110V/220V 50HZ |

| Power switch | Air switch |

| Relative humidity | not more than 85%RH |

| Environment temperature | 5~30℃ |

| System control mode | PLC control |

| PCB size | 30mm*30mm—420mm*320mm |

| Weight | Approx.100KGS |

Leave message