- Welcome to OUBEL !

- +86 755 2954 6287

- sales@obsmt.com

Semi-auto Selective Conformal Coating Machine

Shop

Desktop Semi-auto Selective Conformal Coating Machine

April 8, 2022

Automatic Wave Soldering Machine SE-300

April 11, 2022Semi-auto Selective Conformal Coating Machine

Model: OB-SGC331A

Brand: OUBEL

Delivery Time:4-10 working days

Semi-auto Selective Conformal Coating Machine is used for PCB conformal coating. Anticorrosion,waterproof,dustproof for PCB.

Semi-auto Selective Conformal Coating Machine

Features:

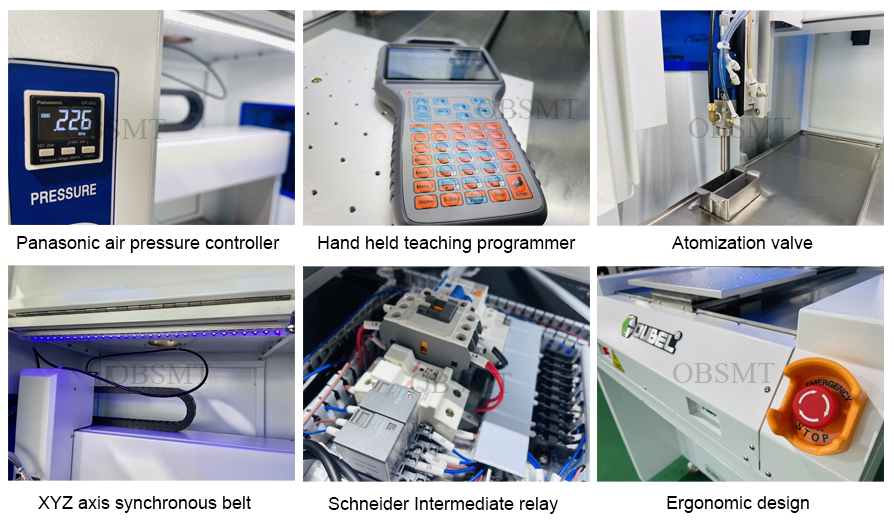

1. The hand-held teaching programmer supports both Chinese and English interfaces, which is simple and easy to learn. It is equipped with special personnel to guide and use. It can be basically mastered in about 30 minutes.

2. The system can store hundreds of processing files, and each file can support 8000 instructions. It can be called out when in use. It supports DXF and PLT file import and automatic path optimization.

3. High end brand configuration, research control stepping motor, Taiwan Shangyin guide rail, Japan Omron photoelectric switch, Italy elatai belt, research control driver, Taiwan Mingwei power supply, red wave switch.

4. According to different requirements, the coating speed / glue amount / coating track (space point, line, arc, etc.) can be set separately.

5. Customized small atomization valve as standard. The stable air pressure system maintains the consistency of glue output and can more accurately and effectively control the edge definition.

6.Tthe whole plate plus heavy platform bottom plate ensures the perpendicularity of XYZ axis. The machine plus sheet metal structure is solid, beautiful, high precision and guaranteed quality.

7. Glue supply device: composed of glue storage barrel and stainless steel cleaning barrel The pressure barrel is composed of air conditioner, safety valve, vent valve, discharge port and inner barrel (pneumatic stirring type can be selected. The pneumatic motor of the pressure barrel can stir by itself to keep the paint in the barrel uniform. In the spraying operation, there will be no color difference due to paint precipitation).

8. Air extraction device: an air outlet is reserved at the top.

9. Lighting detection part: the equipment is equipped with LED lighting system and its own leduv detection light source, which can be converted through the change-over switch. The ultraviolet light source is used to detect the coating of three anti paint on PCB board, which is convenient and practical.

10. Soaking and spitting device: the self-made stainless steel container is used, with ingenious design and convenient replacement. When spraying without workpiece, it can automatically soak the glue gun, which can effectively prevent the glue gun and hose from being blocked due to the drying of glue.

11. The equipment is equipped with automatic cleaning function. When the equipment is shut down, it is switched to the cleaning mode through the installation and replacement switch. The cleaning liquid in the pressure bucket of cleaning liquid will be pressed into the spray gun through the pressure bucket to complete automatic cleaning without manual disassembly and cleaning of the spray valve.

Specifications:

| Model | OB-SGC331A | |||||||

| Dimensions |

770*1050*1540mm |

|||||||

| Weight | 100kg | |||||||

| Working range | 300/300/100 | |||||||

| Moving parts | XYZ axis synchronous belt is standard configuration, and Z axis is optional for screw rod | |||||||

| Valve quantity | 1 | |||||||

| Valve type | Atomization valve | |||||||

| Coating accuracy | Min. coating width: 5-15mm | |||||||

| Exhaust fan | AC220V 50/60Hz | |||||||

| Power | AC220V 50/60Hz | |||||||

| Air source | 5-7kg/cm² | |||||||

| Total power | 2KW | |||||||

| X axis range | 300 | |||||||

| Y axis range | 300 | |||||||

| Z axis range | 100 | |||||||

Leave message