- Welcome to OUBEL !

- +86 755 2954 6287

- sales@obsmt.com

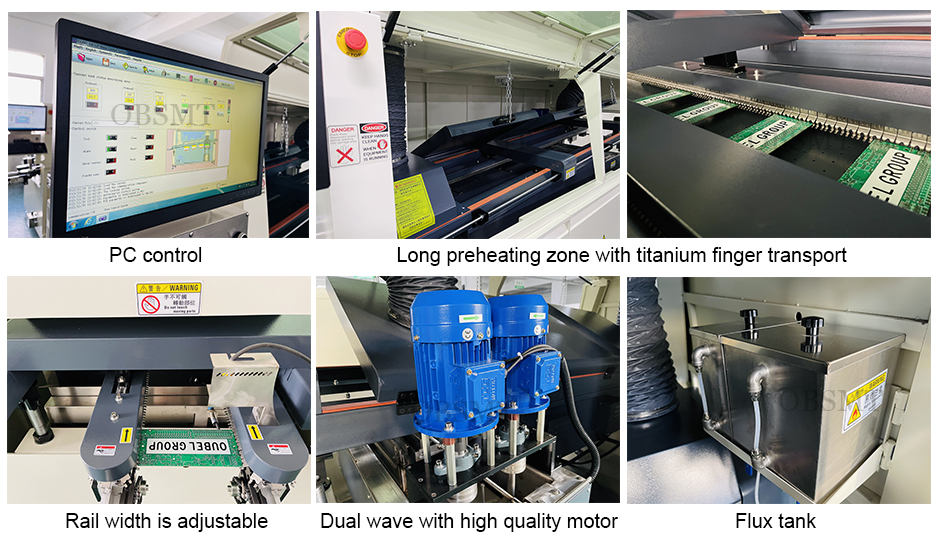

Large Wave Soldering Machine SE-350-PC

Shop

Auto PCB destacker Loader

December 25, 2017

Mini wave soldering machine

December 25, 2017Large Wave Soldering Machine SE-350-PC

Model: SE-350-PC

Brand: OUBEL

Delivery Time: 20-30 working days

Large wave soldering machine is used for welding the DIP chips . Double wave +cooling zone

Large Wave Soldering Machine SE-350-PC

Features

1.Appearance design: novel, plastic spraying process can not drop paint, durable;

2.Hot air preheating: no blind area hot air preheating area, efficient heat conduction; Thick insulation layer, energy saving;

3.Alloy chain claw: high strength, long life;

4.Adjustable nozzle design: wave peak can be adjusted with the width of PCB board, greatly reducing the amount of tin oxidation when welding PCB small board;

5. Transmission mechanism: adopt precise modular design, accurate transmission, long life, easy maintenance;

6.Transportation system: closed loop control. Stepless speed regulation, precise control of PCB preheating and welding time;

7.Heating system: PID closed-loop temperature control, stable and reliable temperature control;

8.Flux spray device: step motor closed-loop automatic tracking spray system, spray width and spray time automatic adjustment, and can be set in advance and extend the spray time as required; Isolated design, pull-out, and removable, easy to clean and maintain;

9.Control system: intelligent control program, the use of brand electrical appliances, to ensure the stable operation of equipment;

10.Man-machine interface: the use of brand computers, to ensure the reliability and stability of the system;

11.Automatic switching machine: according to the date, time and temperature control parameters set by the user;

12.Fault prompt: the system fault self-diagnosis, the cause of automatic display, troubleshooting method at any time query;

13.Economic operation: automatic welding flux spraying, automatic crest, minimize the amount of flux and tin oxidation;

14.Protection system: short circuit and overcurrent protection, to protect the key electrical components of the equipment.

Specifications

| Model | SE-350-PC |

| Conveyor height | 750±50mm |

| Conveyor direction | L-R/R-L |

| Conveyor speed | 0-2.0m/min |

| PCB Working width | 0~350mm adjustable (standard) |

| Preheating zone length | 1500mm |

| Preheating zone quantity | 3 |

| Preheating temperature | Room temperature~250℃ |

| Preheating zone power | 10.5kw |

| Wave quantity | Dual wave |

| Conveyor path gradient | 3~7° |

| Solder type | Lead free /lead tin |

| Solder volume | 330 kg |

| Solder temperature | Room temperature~350±1℃ |

| Component height | Max.100mm |

| Temperature control type | P.I.D+SSR |

| Solder flux | 10~100ml/min |

| Flux Capacity | Max5.2L |

| Wave height | 0-12mm adjustable |

| Controller | PLC+PC |

| Power | 3P 5 Wires (5W,3P) 380V |

| Power for heating up | 22.5kw |

| Power for operation | Approx.6.5kw |

| Air supply | 4-7kg/cm2 |

| Weight | Approx.1000kg |

| Dimensions L*W*H | L3600*W1350*H1700mm |

Leave message