- Welcome to OUBEL !

- +86 755 2954 6287

- sales@obsmt.com

PCB Plating Machine

Shop

Online Dual Spindle PCB Cutting Machine

January 15, 2025

Automatic SMD Tray Taping Machine

February 14, 2025PCB Plating Machine

Model: OB-QB400

Brand: OUBEL

Delivery time: 15-20 working days

Description

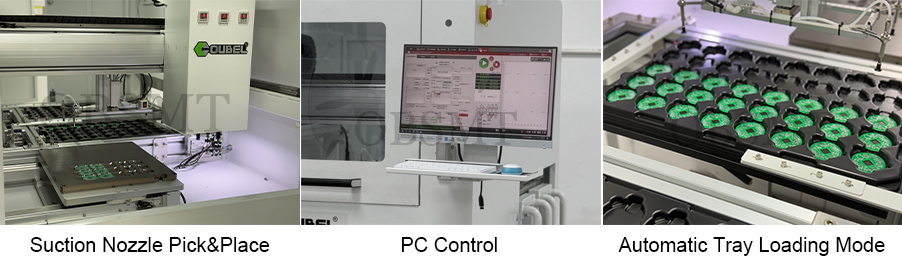

Used for plating PCB after milling cutter cutting,Suction Nozzle Pick&Place,High Efficiency!

Leave message

Description

PCB Plating Machine

Technical Requirement:

1.Maximum movement speed of the motion axis is 1000mm/sec;

2.Visual inspection and PCB plating functions;

3.Transportation method is vacuum suction nozzle transport;

4.Two sets of suction heads.one set for transport PCB,one set for transport tray;

5.High Transport Accuracy + 0.15mm;

6.The suction source is a vacuum pump or vacuum generator;

7.Inovance AC servo motor drive mode;

8.TBl grinding screw/HlWlN guide rail,SMC or AirTAC cylinder,CcD assisted programming method;

9.The lifting mechanism is driven by an AC brake motor.

Details:

Specification:

|

Model

|

OB-QB400

|

|

Dimensions

|

1690*1500*1651mm

|

|

Max size of vacuum formed tray

|

350*350MM

|

|

Usage Function

|

Plating the PCB board after cutting

|

|

Repeatability

|

±0.02MM

|

|

Maximum moving speed

|

X,Y, Axis: 1000mm/s, Z-axis 500mm/s

|

|

Transportation method

|

Vacuum Suction

|

|

Screw/guide rail

|

Taiwan TBI screw/Taiwan HIWIN guide rail

|

|

CCD camera (optional)

|

Hikvision high-speed camera

|

|

Pick up head

|

2/4pcs(optional)

|

|

Program teaching method

|

Teaching Box/CCD Teaching

|

|

Control mode

|

PC precision eight axis control system

|

|

Cylinder, solenoid valve brand

|

SMC or AirTAC

|

|

X. Y-axis drive mode

|

Inovance AC servo drive

|

|

Industrial control host

|

Industrial control computer (WIN10 system)

|

|

Power

|

AC220V 50/60HZ

|

|

Dimension

|

L*W*H(1690*1500*1651mm)

|

|

Weight

|

Approx.700kgs

|

Leave message