- Welcome to OUBEL !

- +86 755 2954 6287

- sales@obsmt.com

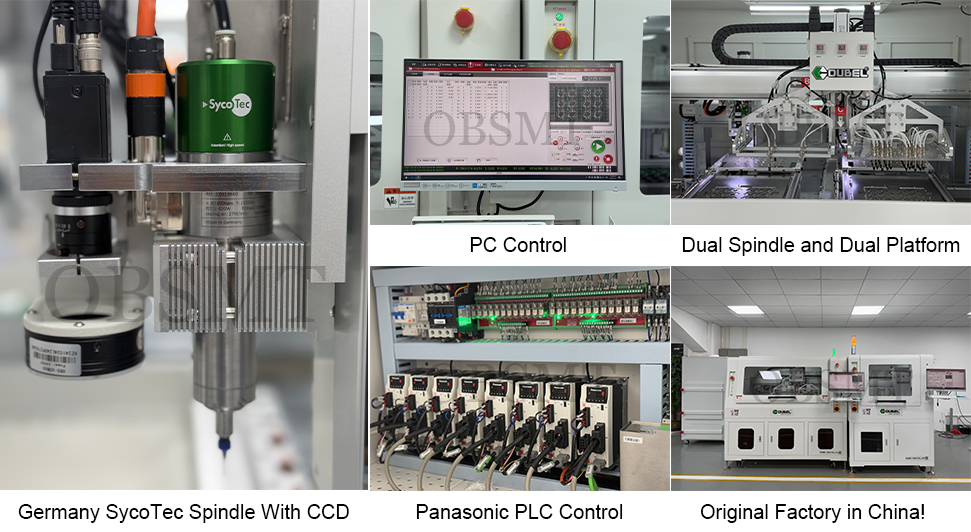

Online Dual Spindle PCB Cutting Machine

Shop

CNC Machining Fixture

July 10, 2024

PCB Plating Machine

January 15, 2025Online Dual Spindle PCB Cutting Machine

Model: OB-QL820

Brand: OUBEL

Delivery time: 15-20 working days

High-speed spindle to quickly cut multiple connected PCB boards according to the edited path for automatic segmentation.Dual spindle dual platform, milling cutter cutting.

Online Dual Spindle PcB Cutting Machine

Technical Requirement

1.X. Y-axis maximum movement speed 1000mm/sec;

2.Cutting function:straight lines,arcs and so on;

3.Cutting method is high-speed spindle rotation milling pin;

4.Panasonic AC servo motor drive mode;

5.TBl grinding screw/HIWlN guide rail;

6.The cutting method is dual spindle asynchronous up cutting mode;

7.The dust collection method is the upper dust collection mechanism;

8.The alignment system automatically locates and corrects based on the MARK point or the positioning point on the fixture;

9.The operation interface is a window editable control operation color interface, whole board puzzle, CCD image teaching programming method;

10.The material retrieval mechanism adopts a vacuum suction cup fixture;

11.The tray positioning fixture is reliable in positioning and easy to adjust and replace;

12.The board output method is to use the carrier to output the board (after cutting, the PCB board is placed inthe carrier and sent out to the later stage of the process).

Details:

Specification:

|

Model

|

OB-QL820

|

|

Dimensions

|

1900*1340*1587mm

|

|

Cutting Size

|

300*350MM

|

|

Cutting function

|

Lines, points, L-shapes, arcs, and circles

|

|

Processing table

|

Dual worktable

|

|

Cutting Accuracy

|

±0.05MM

|

|

Repeated positioning accuracy

|

±0.01MM

|

|

Highest speed

|

X. Y1,Y2 : 1000mm/s, Z: 800mm/s

|

|

Spindle

|

SYCOTEC(Germany)

|

|

Blade change mode

|

Automatic change

|

|

Saw blade motor speed

|

MAX:60000rpm

|

|

Tool monitoring

|

Automatic tool sinking and tool breakage (optional)

|

|

Cutting Speed

|

5~100mm/s(adjustable)

|

|

PCB Thickness

|

0.3-3.0MM

|

|

Program teaching methods

|

Teaching of whole board puzzle and drawing lines in pictures

|

|

Control mode

|

PC precision multi axis control system

|

|

Motor shaft drive mode

|

Panasonic A6 series servo drive

|

|

Applicable milling cutter size

|

0.8-3.0mm

|

|

Electrostatic treatment

|

Electrostatic eliminator (high-frequency ion air nozzle)

|

|

Screw/guide rail

|

TBI grinding screw/HIWIN guide rail

|

|

Width Adjustable

|

Automatic Adjust

|

|

Transport direction

|

Left in and right out

|

|

Transport mode

|

Vacuum Suction

|

|

Industrial control host

|

Industrial computer

|

|

Power

|

1P AC220V 50/60HZ

|

|

Main Cutter Weight

|

900KGS

|

|

Dust collector voltage

|

3P AC380V

|

|

Dust Collector Size

|

L665mm*W635mm*H1610mm

|

|

Dust Collector Weight

|

Approx.155kgs

|

|

Dust Collector Power

|

3HP

|

|

Dust collection method

|

Lower dust collection/upper dust collection (optional)

|

Leave message