Multi-Function Cleaning Machine

Shop

Electric Stencil Cleaning Machine

June 25, 2021

SMT Nozzle Cleaning Machine

June 25, 2021Multi-Function Cleaning Machine

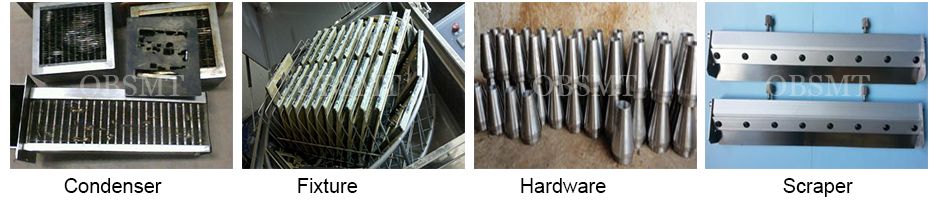

Multi-Function Cleaning Machine is Used for SMT, DIP fixture cleaning, scraper, condenser cleaning, all kinds of workpiece surface cleaning, all kinds of hardware parts after machining cleaning, equipment after the removal of the parts cleaning, auto parts, all kinds of shell, box and other surface and hole wall residual pollutants

Multi-Function Cleaning Machine

Features:

1.Automatic cleaning mode: When the machine is running, the workpiece in the cleaning basket with the cleaning basket rotation, while the high pressure spray system sprays the heating cleaning fluid, so that the stencil can be cleaned, rinsed and dried automatically in all directions;

2.Visualization of the whole process: Visual window and LED light device, cleaning process at a glance;

3.The most scientific nozzle design (patent): Adopting upper, lower and side distribution — completely solve the cleaning blind area, spray arm, nozzle can be disassembled;

4.Visualized nozzle pressure can be adjusted: it solves the problem of collision and splash of small workpiece size when it is sprayed with high pressure during cleaning;

5.Entering and exiting Windows are installed to protect personal safety, standard diluent tank \ rinsing tank heating system, greatly improve the cleaning efficiency. Reduce cleaning time;

6.Comprehensive cleaning system: compatible with running water washing or chemical cleaning, for SMT; THT PCBA after welding surface residual rosin, water-soluble flux, no-cleaning flux/solder paste and other organic and inorganic pollutants to thoroughly and effectively clean;

7.Machine material: 304 stainless steel, acid resistance, alkaline and other cleaning fluid;

8.The built-in filter device can realize the recycling of solvent and reduce the amount of solvent;

9.Has emergency stop button, leakage protection function in case of failure;

10.Lower operating cost: The built-in filter device can realize the recycling of solvents and reduce the consumption of solvents. At the end of cleaning, compressed air blowing mode is adopted: the residual liquid in the pipeline and pump is recovered, which can effectively save 50% of the cleaning agent.

Application:

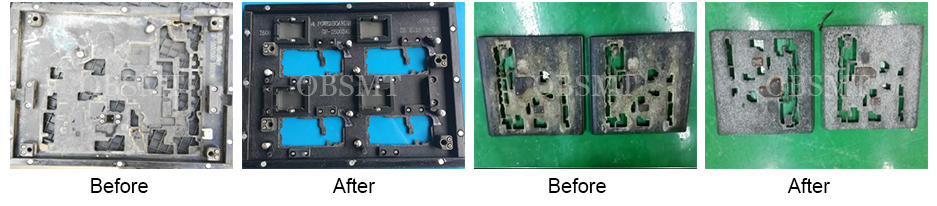

Result:

Specifications:

| Model | OB-C700S |

| Dimensions | L1350 * W1650 *H1750 (mm) |

| Cleaning area size | Ø1000mm ×520mm(H) |

| Voltage | 5P,380V |

| Power | 18KW |

| Air supply | 0.45Mpa ~ 0.7Mpa |

| Weight | 650KGS |

| Spray tank diluting tank heater power | 9KW |

| Cleaning time | 0~99 minutes (adjustable) |

| Cleaning temperature (liquid) | Room temperature ~70℃ (adjustable) |

| Rinsing time | 1 min/time (1-59 times/adjustable) |

| Rinsing temperature (DI water) | Room temperature ~70℃ (adjustable) |

| Drying time | 0~99 minutes (adjustable) |

| Range of upper spray arm height | 400—520mm(adjustable) |

Leave message