- Welcome to OUBEL !

- +86 755 2954 6287

- sales@obsmt.com

Economic High-End Lead Free Wave Soldering Machine SE-250T

Shop

Middle Size Wave Soldering Machine With PC SE-300-PC

April 26, 2018

Automatic THT plug in line

April 26, 2018Economic High-End Lead Free Wave Soldering Machine SE-250T

Model: SE-250T

Brand: OUBEL

Delivery Time: 10-15 working days

Economic High-End Lead Free Wave Soldering Machine SE-250T

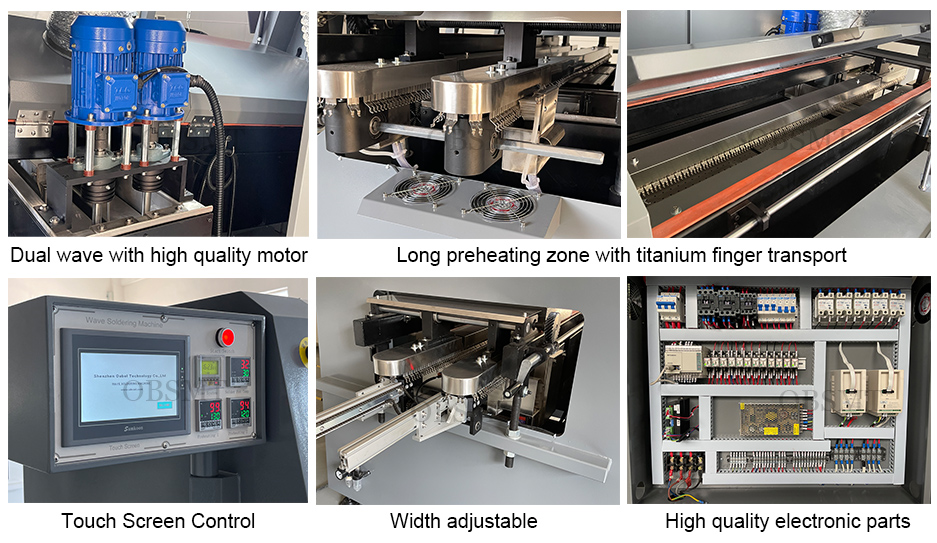

Touch screen +PLC controller. Dual wave.

Titanium finger conveyor.

Economic High-End Lead Free Wave Soldering Machine SE-250T

Features

1.Open type streamline shell design, beautiful appearance, easy to clean up.

2.The solder furnace is made of alloy material. High strength and high hardness special aluminum alloy guide, long service life.

3.The touch screen + professional PLC control technology is used to ensure the reliability and stability of the system.

4.step spray device, can be automatically adjusted with the width of PCB, effectively saving the economic process.

5. Tin wave peak adopts electronic stepless frequency control, independent control of wave height.

6.Isolation device, flux smoke from the exclusive exhaust and recovery channels to meet the environmental requirements.

7.Users can automatically set the date, time, temperature control parameters of the automatic switchgear.

8.Micro chemical pump, propanol cleaning agent, automatic circulation cleaning chain claw.

9.The three section of independent preheating, hot wire device, fully stimulate the activity of flux, and get good welding effect. The heat is directly radiated to the bottom of the PCB plate, and the heat is fast and the service life is long.

10.Die-casting alloy claw, no sticky tin, no deformation, long life, transport PCB stable and reliable.

11.The whole process of transparent observation window is convenient to observe the production and maintenance operation.

12.The transport system adopts variable frequency speed control, PID closed loop control, and the transportation speed is stable.

13.The stored parameters can be invoked quickly, and the operating variables set the process consistency in PCB.

14.Meet PCB auto wave,to minimize the amount of tin oxidation.

15.The temperature control system adopts the closed loop control mode of PID, and the temperature control is stable and reliable. Short circuit and overcurrent protection system.

16. The operating system has a huge memory window program that improves the automated production and management records to a higher level.

Specifications

| Model | SE-250T |

| Conveyor height | Max.760±10mm |

| Conveyor direction | L-R/R-L |

| Conveyor speed | 0-2.0m/min |

| PCB Working width | 0~250mm adjustable (standard) |

| Preheating zone length | 800mm |

| Preheating zone quantity | 2 |

| Preheating temperature | Room temperature~250℃ |

| Wave quantity | Dual wave |

| Conveyor path gradient | 3~7° |

| Solder type | Lead free /lead tin |

| Solder volume | 180 kg |

| Solder temperature | Room temperature~350±1℃ |

| Solder tank size | 650*290*155mm |

| Temperature control type | P.I.D+SSR |

| Solder flux | 10~100ml/min |

| Refrigeration temperature | Below 10℃ |

| Sprayer Moving type | SMC cylinder |

| Power | 3P 5 Wires (5W,3P) 380V |

| Power for heating up | 11kw |

| Power for operation | Approx.4kw |

| Air supply | 3kg/cm2 |

| Weight | Approx.300kg |

| Dimensions L*W*H | 2600*1200*1600mm |

Leave message