- Welcome to OUBEL !

- +86 755 2954 6287

- sales@obsmt.com

2m IR curing oven

Shop

Automatic PCB lead cutter

January 2, 2018

Automatic selective wave soldering machine-SMART-FS350

April 19, 20182m IR curing oven

Model: OB-CO2000

Brand: OUBEL

Delivery Time: 15-30 working days

IR curing oven is used for baking the PCB after the conformal coating machine.

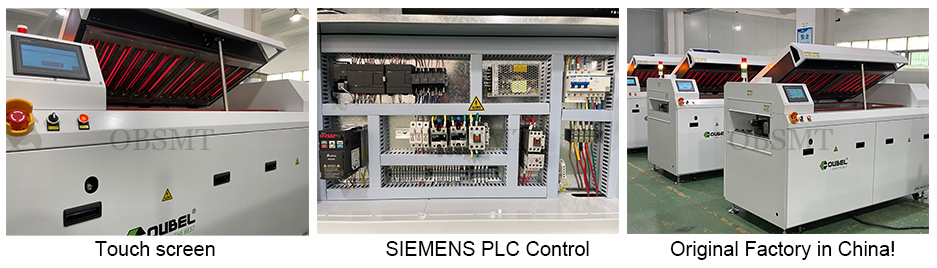

Touch screen+PLC controller.

Guide rail transmission.

2m IR curing oven

Features

Controlling system

1.Temperature controlled meter control, simple operation.

2.Each zone control by PID temperature controlling, temperature control more accurate for multi zones.

Heating system

1.Motor runs stable and reliable.

2.Using infrared plus micro-tube hot air circulation heating method, the heating temperature of each zone can be individually controlled, greatly improve the circulation of hot air flow, rapid heating, the maximum temperature is up to 150 ℃; hearth and interior are use of special materials, the external thicker insulation cotton ensure minimum heat loss;

Conveyor system

1.Transmission chain fully closed loop control,

2.High-strength guide rail design, thermal deformation, to ensure accuracy.

3.Rail width adjust by manual , control panel, easy to use.

4.Efficient energy saving: start with a very low average power.

Specifications

| Model | OB-CO2000 | OB-CO3000 |

| Dimensions | 2000*960*1250mm | 3000*960*1250mm |

| PCB conveyor height | 900±20mm | 900±20mm |

| PCBA width range | 50~400mm | 50~400mm |

| Direction | L-R or R-L (optional) | L-R or R-L (optional) |

| Conveyor speed | 700~2000mm/min | 700~2000mm/min |

| Conveyor motor power | 120w | 120w |

| Temp control range | ±1.5℃ | ±1.5℃ |

| Temp control precise | ±5 | ±5 |

| Heating zones | 2 | 3 |

| Heating time | Approx.20min | Approx.20min |

| Power | 5W3P 380V | 5W3P 380V |

| Start power | 12KW | 16KW |

| Average power | Approx.3KW | Approx.4KW |

| Weight | Approx.450Kgs | Approx.500Kgs |

Leave message