- Welcome to OUBEL !

- +86 755 2954 6287

- sales@obsmt.com

Fixture Cleaning Machine

Shop

SMT Suction Nozzle Cleaner

May 13, 2019

High-End PCB/PCBA Cleaner

May 13, 2019Fixture Cleaning Machine

Model: OB-FC750

Brand: OUBEL

Delivery Time:4-10 working days

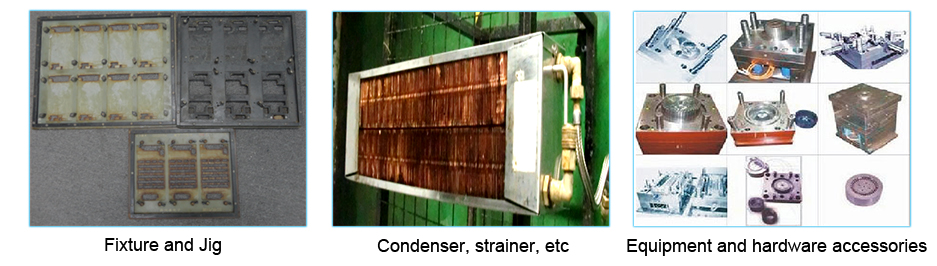

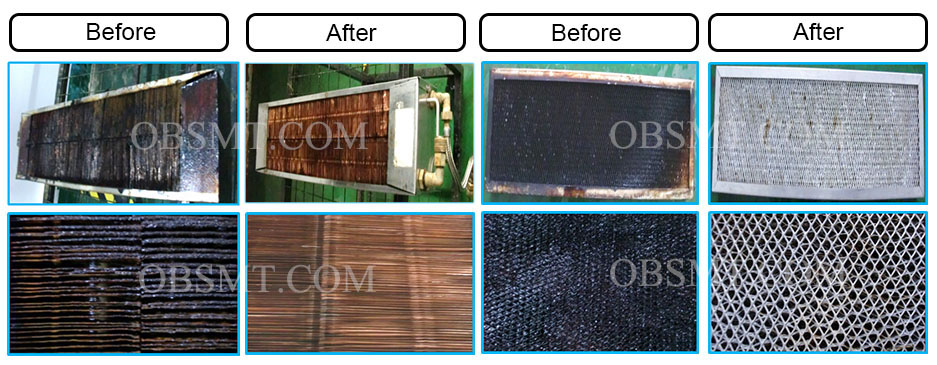

is used to clean grease, flux, dusts on the surface of all kinds of SMT fixtures,tray, reflow oven cooler and filter, wave-soldering oven claw, chains, and nets…etc.

**E:sales@obsmt.com

Fixture Cleaning Machine

Features:

1. Ensure thorough cleaning effect, so that your products in the oven from pollution.

2. The operation of the equipment is more environment-friendly, energy-saving, more efficient, more stable, and the oven temperature curve is more perfect.

3. Fully automatic cleaning can be realized to improve the cleaning environment.

4. Consistency of machine cleaning ensures controllable cleaning quality.

5. Integration of cleaning and rinsing.

6. Closed loop filtration system for cleaning fluid, lower operating cost;

7. The machine adopt stainless steel ,it is strong and durable.The cleaning liquid is acid and alkaline resistant.

Apply to:

Grease, flux, dusts on the surface of all kinds of SMT fixtures,tray, reflow oven cooler and filter, wave-soldering oven claw, chains, and nets…etc.

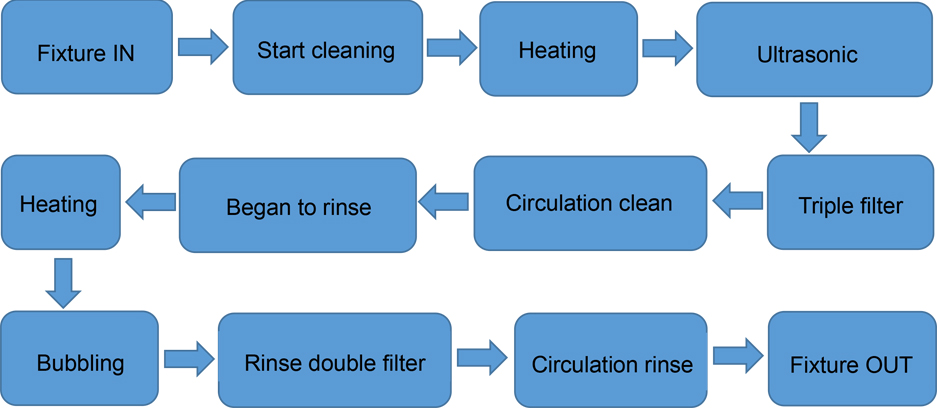

Process:

Specifications:

| Model | OB-FC750 |

| Dimension | 1850(L) ×1160(W) × 1060(H)mm |

| Cleaning way | Ultrasonic + bubbling + overflow |

| Cleaning/rinsing dimensions | 705(L)mm ×675 (W)mm × 300 (H)mm |

| Clean tank capacity | 230L |

| Power | Heat :9 KW*2; Ultrasonic :5.4kw, the total power is about 24KW |

| Weight | Appro 400Kg |

| Air supply | 0.45Mpa~0.7Mpa |

| Gas consumption | 200-400l /Min |

| Clean Time | 5-15Mins |

Leave message