- Welcome to OUBEL !

- +86 755 2954 6287

- sales@obsmt.com

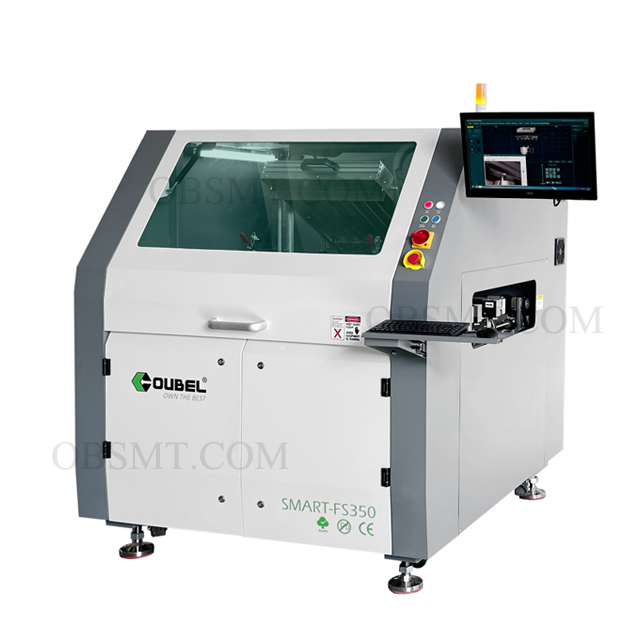

Automatic selective wave soldering machine-SMART-FS350

Shop

Automatic selective wave soldering machine-SMART-FS350

Model: SMART-FS350

Brand: OUBEL

Delivery Time: 30 working days

Automatic selective wave soldering machine

PLC+PC controller.

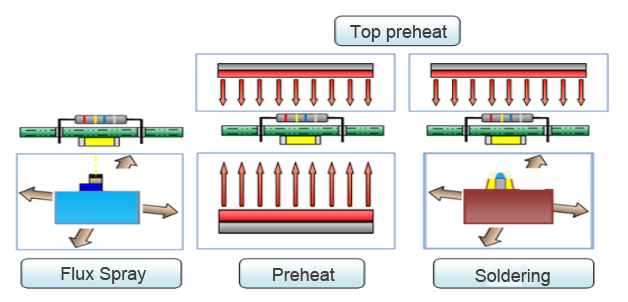

Spraying,Preheating and welding units in one machine.

Automatic selective wave soldering machine

Features

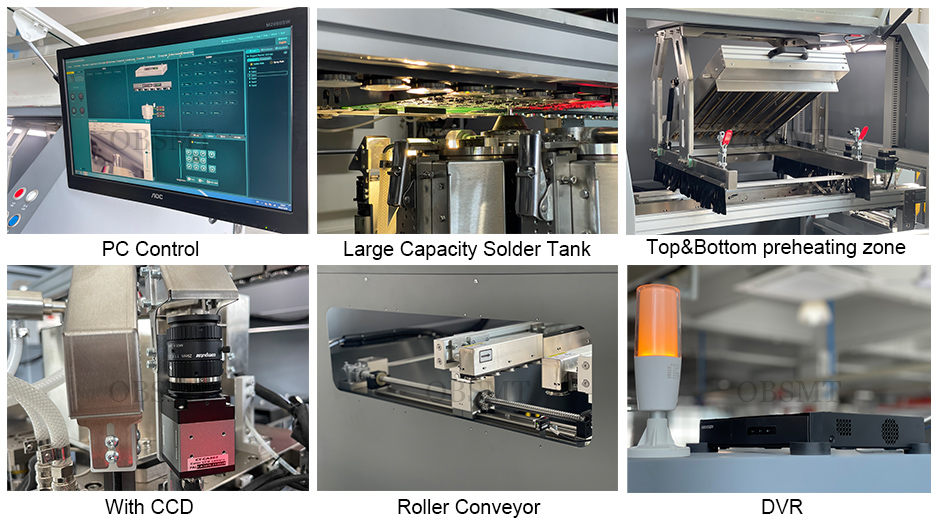

1.Equip with spraying, preheating and welding units which can complete the whole welding process in a small machine;

2.Small size, small footprint, length:1435mm;

3.Standard electromagnetic pump solder tank, no wear parts, easy maintenance;

4.Rotary track design which allows loading and unloading PCB on the same side of the machine;

5.Standard equipped with teaching camera, spray cleaning function;

6.Realtime monitoring and recording of welding process;

7. Transmission system adoption a roller conveyor,increase welding space,better close to the edge components of welding;

8. Adopts precise nozzle with 130um diameter which is imported from Germany and can uniformly spray flux in the required welding area.The minimum injection area is3mm which saves atleast 90%flux compared with the traditional spraying;

9. All the movements are drive d by servomotor.The movements are stable and smooth.The precision accuracy is around 0.05mm;

10. The soldering module has high precision axis system to ensure the accurate soldering path and with particular process,the system will eliminate the chance of bridging;

11. Process monitor screen and automatic soldering wave height detecting are very friendly for users.

Specifications

| Model | SMART-FS350 | |||||||

| Overall dimension(mm) (Not include the keyboard, indicator light and monitor) | 1435(L)*1800(W)*1670(H) | |||||||

| Weight | Approx.1050kgs | |||||||

| PCB Top Side Clearance | 120mm | |||||||

| PCB Bottom Side Clearance | 60mm | |||||||

| PCB process edge | ≥3mm | |||||||

| Conveyor Height From Floor | 900±20mm | |||||||

| PCB Conveying Speed | 0.2-10m/min | |||||||

| Max PCB Weight | ≤5kgs | |||||||

| PCB Thickness With Jig | 1-6mm | |||||||

| Conveyor Width Adjustment Range | 50-450mm | |||||||

| Conveyor Width Adjustment Mode | Electric | |||||||

| PCB Conveying Direction | L-R | |||||||

| Air Input Pressure | 0.6Mpa | |||||||

| Nitrogen Supply | Offered by customer | |||||||

| Nitrogen Input Pressure | 0.6Mpa | |||||||

| Nitrogen Consumption | 1.5m³/h | |||||||

| Required Purity of Nitrogen | ≥99.999% | |||||||

| Supply Voltage | 380VAC | |||||||

| Frequency | 50/60HZ | |||||||

| MaxPower Consumption | <12kw | |||||||

| Max Current | <25A | |||||||

| Ambient Temperature | 10-35℃ | |||||||

| Machine Noise Level | <65dB | |||||||

| Communication Interface | SMEMA | |||||||

| Max.Soldering distance of Xaxis | 510mm | |||||||

| Max.Soldering distance of Yaxis | 450mm | |||||||

| Max.Soldering distance of Z axis | 60mm | |||||||

| Min outer diameter of nozzle | 5.5mm | |||||||

| Nozzle inner diameter | 2.5-10mm | |||||||

| Max soldering wave height | 5mm | |||||||

| Solder pot capacity | Approx.13kg(Sn63pb)/Approx.12kg(lead-free) | |||||||

| Max soldering temperature | 330℃ | |||||||

| Soldering heating power | 1.15kw | |||||||

| Preheat temperature range | <200℃ | |||||||

| Heating power | 6kw | |||||||

| Top side preheating | Hot air | |||||||

| Max.stroke of Xaxis | 510mm | |||||||

| Max.stroke of Yaxis | 450mm | |||||||

| Spray height | 60mm | |||||||

| Location speed | <200mm/s | |||||||

| Fluxbox capacity | 2L | |||||||

Leave message