- Welcome to OUBEL !

- +86 755 2954 6287

- sales@obsmt.com

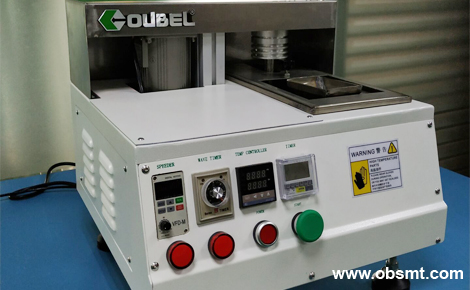

manual selective jet wave soldering machine

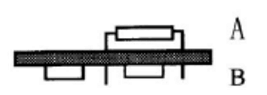

some PCB is SMD +DIP chips mixed together. If we use the traditional wave soldering machine welding process, it may damage the SMD chips which weld before.

Especially for the PCB , SMD chips > DIP (THT) chips.

PCBA

www.obsmt.com

Then to avoid the second weld for the SMD chips , we recommend to use this small selective partial wave soldering machine.

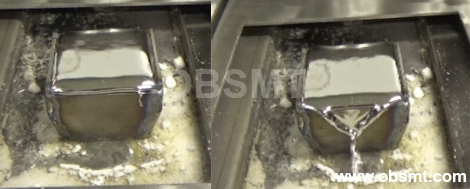

The Welding nozzle can be made according to the different PCB design.

selective soldering machine nozzle

www.obsmt.com

High efficient , low cost, save energy ( no matter for power or solder ,meanwhile protects other chips.)

Solder capacity only 20KGS!

OBSMT JET WAVE soldering

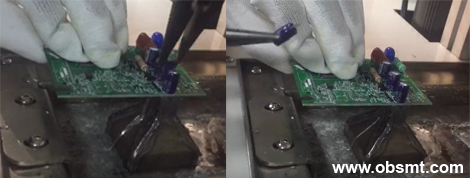

This OB-S310A selective wave soldering machine is also used for repair the PCB, remove the DIP chips. Compare the old method -suction solder gun, it’s higher efficient!

You just need put the PCB welding part to the machine nozzle, then open the wave soldering, all through holes lead melt at the same time.Finally use a pointed-nose pliers or high temperaure glove to take off this chip.

PCBA repaire

www.obsmt.com