- Welcome to OUBEL !

- +86 755 2954 6287

- sales@obsmt.com

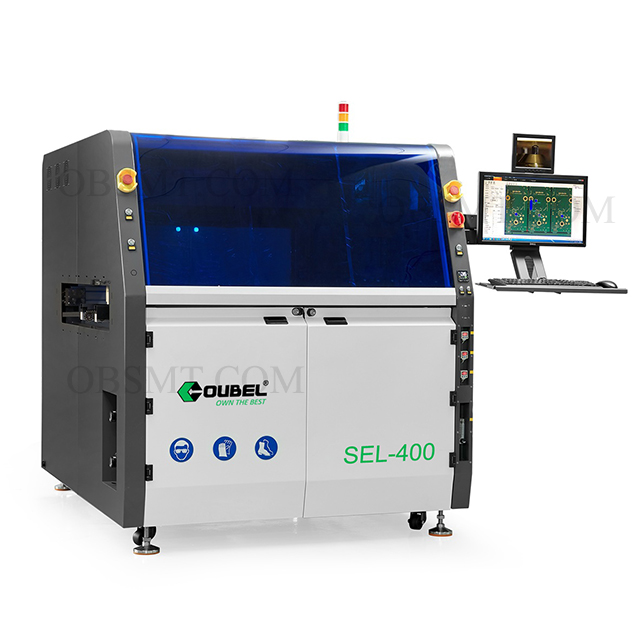

On-Line PCB Selective Soldering Machine SEL-400

Shop

On-Line PCB Selective Soldering Machine SEL-400

Model: SEL-400

Brand: OUBEL

Delivery time: 15-20 working days

Selective wave soldering is a special form of wave soldering invented to meet the development requirements of through-hole components soldering. It is mainly suitable for the soldering of through-hole components in high-end electronic products.

On-Line PCB Selective Soldering Machine SEL-400

Features

1.PCB plate fixed, spray and soldering platform moving;

2.High soldering quality, greatly improve the pass rate of soldering;

3.Modular design of SMEMA online transportation, support customers for flexible line formation;

4.Full PC control. All parameters can set in PC and saved to PCB menu, like moving path, solder temperature, flux type, solder type ,n2 temperature etc, best trace-ability and easy to get repeat soldering quality;

5.Auto wave height calibration function, to check & calibrate wave’s height after every certain pcb, so to keep a very good stability of wave;

6.Can upgraded to be with Mark positioning function, to check PCB`s mark point after every certain pcb;

7.Standard with imported jet valve to get precious fluxing result with small flux dot, please note flux solid content should be less than 10%;

8.Flux is stocked by pressure tank, make sure pressure stable without influenced of amount of flux. The nozzle jam detection function is optional;

9.The XY spray platform is composed of high-precision ball screw and linear slide rail. It is driven by a high-speed servo motor;

10.The nozzle is mounted on the XY platform,The accuracy of repetition and positioning can reach 0.05mm;

11.Bottom preheating is standard equipped in machine, Position is adjustable.IR heater of Top,Efficient and stable IR heat conduction.Design structure for maximizing preheating area.All round high temperature cotton design to ensure temperature stability.Heat-generating and heat-conducting parts and motors adopt top brands.Maintenance plug-in design. tool-free maintenance mode;

12.XYZ platform is composed of high precision ball screw and high-speed motor;

13.Electromagnetic pump coil adopts German imported brand to ensure the stability and reliability of the peak;

14.Solder temperature, N2 temperature, wave height, wave calibration etc all able to set in software;

15.Solder pot is made of Ti, not leakage. With cast iron heater outside, robust & quick heat up;

16.N2 online heating system, to wet the soldering perfectly and reduce the solder dross;

17.Standard with the nozzle automatic cleaning function. How many panels can be set to clean the nozzle;

18.The transmission module is composed of three parts by roller;

19.The spray and soldering transmission tracks are equipped with a stop plate positioning device to ensure the accuracy;

20.The distance of weldable elements on PCB plate edge is much higher than that of chain conveyor structure.

Specifications

| Model | SEL-400 |

| Flux Storage Tank | 1 L |

| Max PCB Size | 500*400mm |

| PCB Top Clearance | 100mm |

| PCB Weight | <8Kg |

| N2 | Purity of N2: 99.998%, 0.3~0.4 MPa,25 L/min,Outer diameter Φ6mm |

| Dimension | L1520*W1650*H1650mm |

| Weight | Approx:1200kg |

Leave message