- Welcome to OUBEL !

- +86 755 2954 6287

- sales@obsmt.com

Full-Tunnel Entire Nitrogen Wave Soldering Machine NXS450

Shop

Nitrogen Dual Wave Soldering Machine SMART-610-H

April 11, 2022

Off-Line Selective Wave Soldering Machine ASEL-300

April 11, 2022Full-Tunnel Entire Nitrogen Wave Soldering Machine NXS450

Model: NXS450

Brand: OUBEL

Delivery time: 15-20 working days

Full-Tunnel Entire Nitrogen Wave Soldering Machine is used for PCB DIP chips welding.Automatic welding, high efficiency.

Full-Tunnel Entire Nitrogen Wave Soldering Machine NXS450

Features

1. Nitrogen Closed-loop Control:A real-time monitoring on nitrogen concentration and PID closed-loop adjusting nitrogen flow to realize the stable PPM value;

2.Increase Solder Stability:By nitrogen protecting can improve the wetting of wave infiltration and promote solder penetration rate to make sure the stable quality;

3. Reduce Solder Defect:The tunnel-based nitrogen wave soldering can reduce solder defect and improve production efficiency with less ocygen content;

4.Save Cost:The equipment maintenance cost could be decreased effectively by a closed preheating enviroment.

Specifications

| Model | NXS450 |

| Conveyor height | 750±20mm |

| Conveyor direction | L-R/R-L |

| Conveyor speed | 300-1800mm/min |

| PCB Working width | 0~450mm adjustable (standard) |

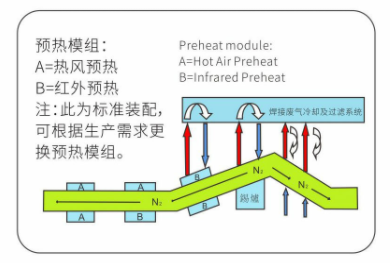

| Preheating zone length | 2250mm |

| Preheating zone quantity | 4 |

| Preheating temperature | Room temperature~250℃ |

| Wave quantity | Dual wave |

| Conveyor path gradient | 3~7° |

| Solder type | Lead free /lead tin |

| Solder volume | 550 kg |

| Solder temperature | Room temperature~350±1℃ |

| Component height | Top.120mm,Bottom.25mm |

| Temperature control type | P.I.D+SSR |

| Solder flux | 10~100ml/min |

| Controller | PLC+PC |

| Power | 3P 5 Wires (5W,3P) 380V |

| Power for heating up | 60kw |

| Power for operation | Approx.10kw |

| Air supply | 4-7kg/cm2 |

| Weight | Approx.2000kg |

| Dimensions L*W*H | 5650*1650*1750mm |

Leave message