- Welcome to OUBEL !

- +86 755 2954 6287

- sales@obsmt.com

Nitrogen Dual Wave Soldering Machine SMART-610-H

Shop

Quality Guarantee DIP Wave Soldering Machine SMART-350-E

April 11, 2022

Full-Tunnel Entire Nitrogen Wave Soldering Machine NXS450

April 11, 2022Nitrogen Dual Wave Soldering Machine SMART-610-H

Model: SMART-610-H

Brand: OUBEL

Delivery time: 15-20 working days

Nitrogen Dual Wave Soldering Machine is used for PCB DIP chips welding.Automatic welding, high efficiency.

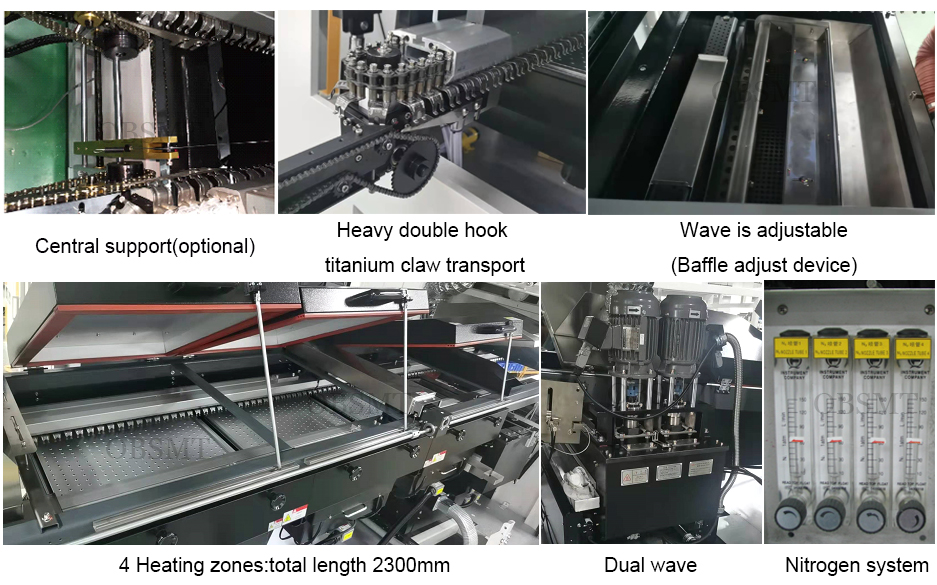

Nitrogen Dual Wave Soldering Machine SMART-610-H

Features

1.The hot air preheating u-shaped heater,long service life,reduce maintenance downtime;

2.Internal reinforcement insulation plus optional external protection device can effectively reduce the heat loss,energy saving up to 20% compare with traditional equipment;

3.Low equipment surface temperature can optimize the working environment;

4.External spray fluxer combined the advantages of inner and independent spray,the spray and machine can be integrated control,no increase in cost;

5. Spray fluxer away from preheating zone,and ensure safety and clean;

6.Transportation of new type titanium alloy heavy duty claw,sectional guide rail design,stainless steel strip supported in guide rail,long life;

7.The solder pot adopts special materials,Anti corrosion coating on surface;

8.Adopt imported precision nozzle,atomization uniformity,high efficient;

9.Nozzle quick released,reduce maintenance time,2 hours to a few minutes;

10.Grid type of mesh,reduce the mesh block by solder fross monthly maintenance extended to six months;

11.Optional solder supply device,reduce the influence of wave height caused by the change of tin solder level.

Specifications

| Model | SMART-350-H | SMART-450-H | SMART-610-H |

| Dimensions | 4445*1582*1735mm | 4445*1582*1735mm | 4445*1742*1735mm |

| Flux Sprayer Dimensions | 1300*1350*1595 mm | 1400*1510*1595mm | |

| Power Supply | AC 380V,50/60HZ(AC 220V3P,50/60HZ is optional) | ||

| Initial/Operating Power | 8.5KW | 9.5KW | 11.5KW |

| Starting Power | 43KW | 43KW | 64KW |

| Air Source | 0.5-0.8Mpa | ||

| Control System | PC+PLC | ||

| Flux Flow | 10-100ml/min | ||

| Exhaust Tube Diameter | φ200mm | ||

| Exhaust Mode | Upward | ||

| Preheat Mode | IR/Hot Air | ||

| Preheat zone number | 4 zones/2280mm | 4 zones/2280mm | 4 zones/2280mm |

| Preheat temp.range | Room Temp.-280℃ | ||

| Temp.control mode | PID+SSR | ||

| Solder pot type | Mechanical pump | ||

| Pot capacity | 480KGS | 550KGS | 800KGS |

| Max.Soldering Temp. | Max:300℃ | ||

| Wave Driving Power | 1/4 HP X2 | 1/2 HP X2 | 1/2 HP X1 1HP X1 |

| Wave Height Control | Inverter | ||

| Heat Up Time | Approx.110min(set 250℃) | Approx.120min(set 250℃) | |

| PCB Conveyor Speed | 300-1800mm/min | ||

| PCB Width | 50-350mm | 50-450mm | 50-610mm |

| Components height | Top:120mm,Bottom:25mm | ||

| Transport height | 750±20mm(Entrance) | ||

| Conveyor angle | 4-7° is adjustable | ||

| Speed control mode | Inverter | ||

| Cooling method | Forced Air Cooling(Option:Chiller) | ||

| N2 system | SMART-350-V2-H-N | SMART-450-V2-H-N | SMART-610-V2-H-N |

| Nitrogen Consumption | 15m³/h,below 1000PPM | ||

| Pressure Nitrogen Source | 0.5-0.8Mpa | ||

| Oxygen Nitrogen Source | ≤10PPM | ||

| Oxygen Analyzer | Optional | ||

Leave message