- Welcome to OUBEL !

- +86 755 2954 6287

- sales@obsmt.com

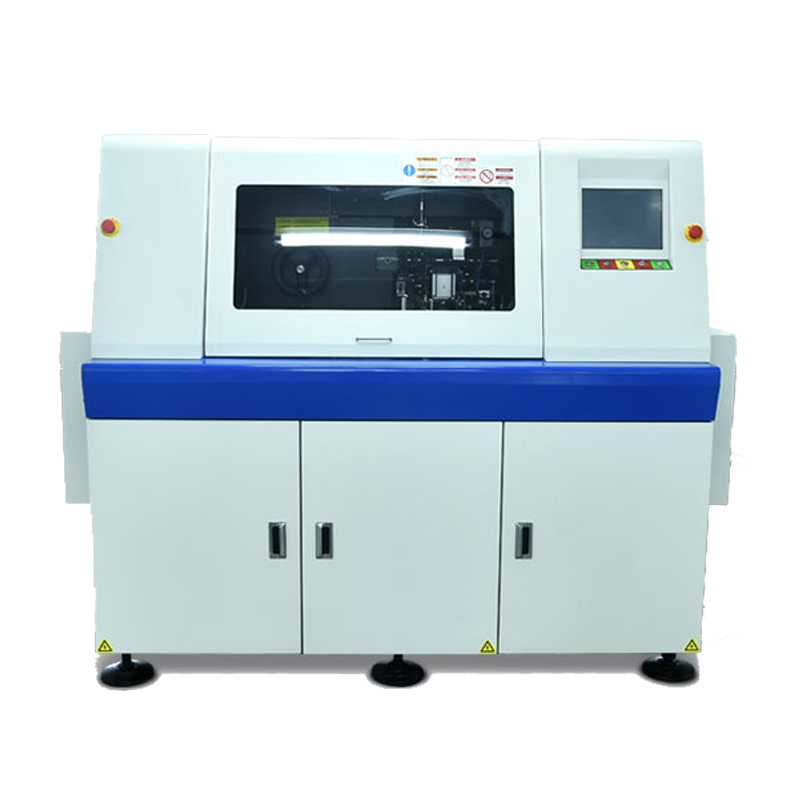

Auto Vertical Plug-In Machine

Shop

Flexible LED Strip Production Line

December 30, 2021

Automatic riveting machine

December 31, 2021Auto Vertical Plug-In Machine

Fully automatic dip inserting machine , servo motor drive, 360 ° insertion angle, high speed and high density plug-in.

Support 2.5/5.0mm span, 7.5/10.0/3.5mm span (option)

Features:

It is driven by servo motor with 360 ° insertion angle to realize high-speed and high-density plug-in.

Plug in defect automatic detection, you can choose the function of automatic interpolation.

Fully automatic upper and lower plate track system, with the upper and lower plate machine to achieve fully automatic process.

Support 2.5/5.0mm span, 7.5/10.0/3.5mm span (option).

The touch screen Chinese interface is high-end, convenient and easy to use.

Compact design, takes up less space.

Specifications:

| Model | OB-NB510 | OB-NB500 |

| Theoretical capacity (CPH) | 22000 | 18000 |

| Actual capacity (CPH) | 16000 | 6000 |

| Actual insertion rate (PPM) | Less than 1000 | Less than 3000 |

| Investment amount (RMB) | 700K-900K | 350K-500K |

| Consumables (RMB / month) | 1K-2K | 1K-2K |

| Service life (years) | 10+ | 2-5 |

Performance parameters

| Power supply | Rated voltage: 3-phase 380V ± 20V Frequency: 50 / 60Hz Rated capacity: about 4.0kva |

| Air source | Supply air pressure: Min 0.45mpa-max 0.8MPa (the operating pressure is 0.45mpa-0.5mpa) Air supply: About 80L / min (a.n.r) |

| Equipment size | W2120mm * d1750mm * h1610mm (excluding signal tower and material rack) |

| Weight | Host weight: About 2000kg (host only) |

| Speed | Quick plug in: 0.168 seconds / point |

| Suitable for components | Spacing: 2.5mm/5.0mm (standard model) mm Spacing: 3.5mm/7.5mm/10.0mm (optional model √) |

| Insert direction | 360 ° direction (1 ° as unit) |

| Interpolation mode | Automatic machine interpolation / manual machine interpolation |

| Recognition mode | Automatic identification |

| Applicable substrate size | Minimum: 50 * 50mm maximum: 500 * 380mm |

| Bending angle | N-shaped 35 ° angle |

| Feeder | 5.0 mm standard feeder (10 pieces) |

OBSMT , 15+ years SMT DIP machines factory in China

Leave message