- Welcome to OUBEL !

- +86 755 2954 6287

- sales@obsmt.com

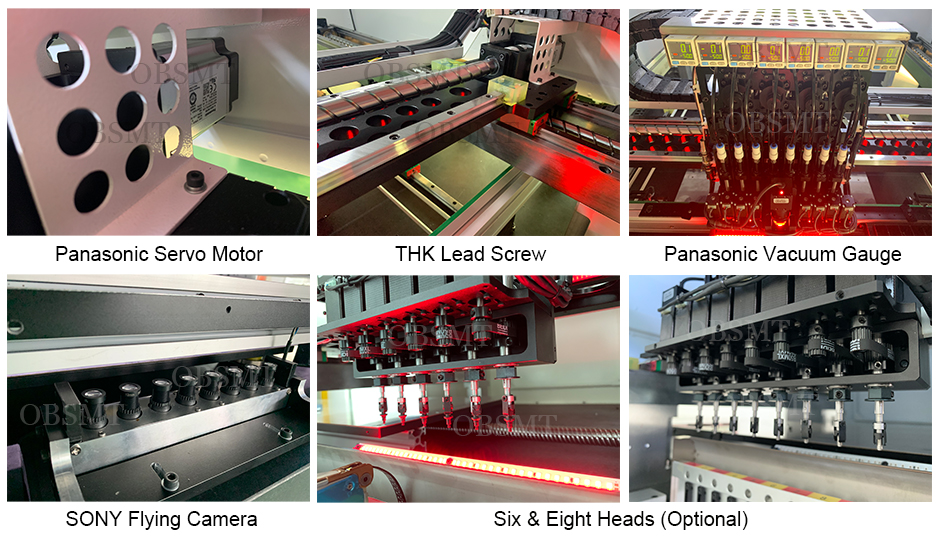

Multi-function 6 heads pick and place machine

Shop

LED Lens Mounter

November 4, 2019

High End Chain Conveyor

December 10, 2019Multi-function 6 heads pick and place machine

Model: OB-H560

Brand: OUBEL

Delivery time: 20-25 working days

In addition to place the traditional long led tube light, also can place bulb light, down light, spot light, ceiling light, LED fence light, LED driving power supply, copper wire string light and so on.

Multi-function 6 heads pick and place machine

Features:

1.Mount: Mount 0603 to 7272 can meet all specifications of SMD LED components. In addition to all the planar LED plane, other electronic components (such as resistors, capacitors) and high power LED and the lens can be produced.

2.precise positioning: positioning block is the most convenient way to position the substrate, the origin of counterpoint, accurate positioning (accuracy less than 0.05mm). Mount angle range of 0-360 degrees, the accuracy of 0.1 degrees. Each suction nozzle is independent of angle, and six element recognition cameras, in addition to LED lamp can mount the traditional., bulb lamp, lamp, lamp, ceiling lamp, guardrail tube, LED drive power, copper lamp series and so on can be freely mounted.

3. high precision: X, Y, W axis are equipped with precision ball screw and guide rail, Z axis 6 sets of imported motor drive, enhance the smooth coordination of equipment movement, reduce abnormal noise, greatly improve the accuracy and speed of the patch.

4. SMT specifications: platform 500X400mm, applicable to the current market of 99% LED products;PCB board can be affixed to various shapes, without clamps.

5.the visual system, visual programming software online programming, which is of high precision digital camera camera, there is no need to manually input elements and positioning coordinates; using visual camera automatic identification, to ensure the accuracy of mount.

6.the software interface is simple and elegant, functional and practical, visual software online programming, display all coordinates in the imposition software, and fine-tuning of the coordinates of the point, in order to achieve high precision mount, without manual input element coordinates, fast and convenient, simple and clear, combined with the actual needs of many LED manufacturers R & D design.

7.YAMAHA Feeder: machine configuration 30pcs 8MM YAMAHA Feida (also optional with Fuji electric Feida), long service life, high stability, fast speed. can increase to 50 feeder slot.

Specifications:

| Product name | Full automatic multi-function pick place machine | |||||||

| Maximum PCB area | 600×400mm | |||||||

| Maximum moving range | X axis600mm, Y axis 400mm | |||||||

| Z axis Maximum moving range | 12mm | |||||||

| Max placement speed | 30000CPH | |||||||

| Typical placement speed | 10000–23000CPH | |||||||

| Movement precision | ±0.05mm | |||||||

| Positioning method | MARK point camera + 6 sets Sony visual camera position+1 set industrial camera | |||||||

| Can mount components | 0402 upper resistor and capacitor parts and LED chips 3528, 5050, meanwhile meet requirement of SOP, SOT chip placement, power driver, control board etc placement and compatible with all kinds of high power chip mount. | |||||||

| Types of production | LED tube light, soft LED strip light,PCB, power supply driver, fence light, display module, switch, display screen etc multi LED application products | |||||||

| Programming method | Automatic Visual camera Positioning programming | |||||||

| Belt type feeder | 8mm, 12mm, 16mm, and 24mm feeder | |||||||

| Number of feeders | can instal 26pcs of standard 8mm feeder | |||||||

| Operating system | WINDOWS 7 | |||||||

| Compressed air | 0.55MPA | |||||||

| Power supply | 220V, 50Hz, 2.0KW | |||||||

| Weight | 1200Kg | |||||||

| Dimensions | 1300MM(L)*1300MM(W)*1450MM(H) | |||||||

Leave message