- Welcome to OUBEL !

- +86 755 2954 6287

- sales@obsmt.com

Nowadays PCB conformal coating process is necessary

New technology for the PCB printing stencil

August 8, 2019

manual selective jet wave soldering machine

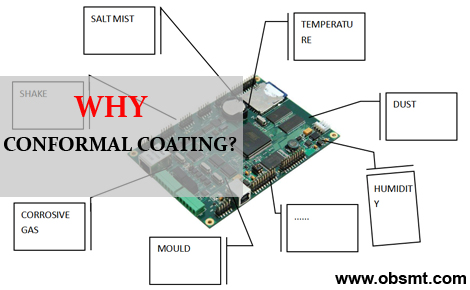

August 13, 2019Nowadays PCB size becomes smaller and more density. The distance between two chips, and the distance between chips to PCB surface are smaller. Environmental factors have more and more influence on PCB. Means we have higher requirement for PCBA.

Meanwhile company pay more and more attention to the quality of products, not only to seek better client’s experience, but also to establish the company’s brand image. For PCBA, the core component of electronic products, this equipment is more important.

What is this ?

CONFORMAL COATING MACHINE— “PROTECTOR OF PCBA”

why conformal coating for PCB www.obsmt.com

conformal coating result under UV light

www.obsmt.com

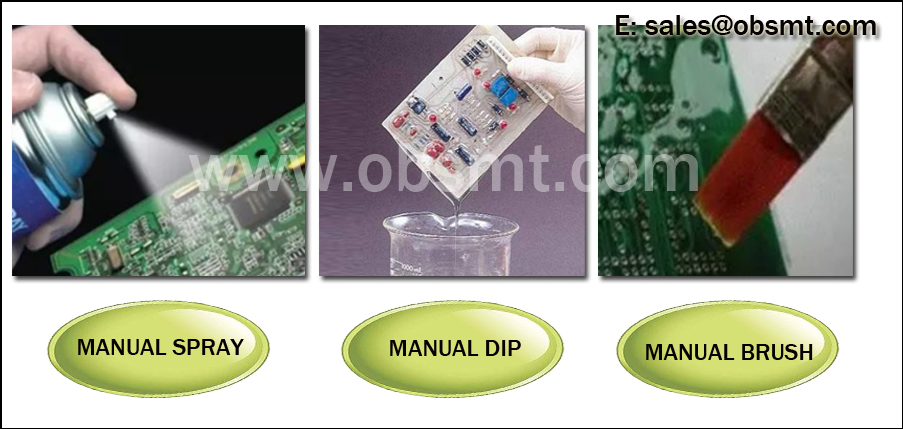

Traditional conformal coating has below problems:

1.Poor consistence of coating quantity or coating thickness!

2.Open type operation, emission pollution is big!

3.The corresponding selection of the coating thickness and the best baking time.

4.Need fixture for selective coating!

5.Poor consistence of the first point and the end point glue coating quantity!

6.Hard to control the coating width for different PCBS!

7.Low coating efficiency , high labor cost!

Old conformal coating process

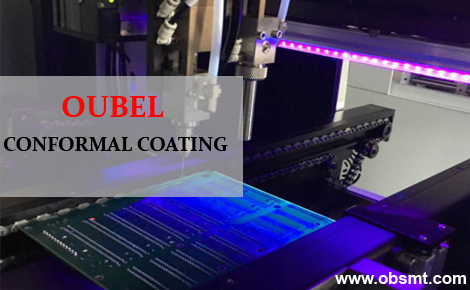

OUBEL Conformal coating machine can solve:

1.Solve the effect the coating quantity because of the factory air source large fluctuation!

2.Solve the coating quantity and thickness difference problem!

3.Solve the PCB uniform reliability after coating!

4.Solve the glue don’t influence by the environment temperature change!

5.Offer different coating valves to meet different coating requirements!

6.Solve the glue leakage of the coating 1st point and end point!

7.The closed coating system can minimize the air pollution in the workshop!

OUBEL conformal coating

www.obsmt.com

Today the market competition is more and more intense, how PCB assembly plant in such an environment can to be invincible. The first point is to reduce its production costs. To achieve this goal, the most important way is to improve the production efficiency of the production line.