- Welcome to OUBEL !

- +86 755 2954 6287

- sales@obsmt.com

New technology for the PCB printing stencil

Feeder Trolley

August 7, 2019

Nowadays PCB conformal coating process is necessary

August 12, 2019As the SMT first process —PCB Printing. SMT stencil is necessary part.

**Etching steel stencil

It is a special SMT mould. Its main function is to help the deposition of solder paste. The purpose is to transfer the precise amount of solder paste to the exact position of empty PCB.

Features:

The smoothness of steel stencil produced by chemical etching process can reach 0.02mm. The etched steel mesh is suitable for PCB plate printing with angular position and spacing greater than or equal to 0.4MM. It is suitable for plate copying and film printing. It can also use CAD/CAM and exposure mode. Depending on different parts, it can be scaled and scaled without calculating the price according to the number of parts, and the production time is fast.

OBSMT SMT stencil

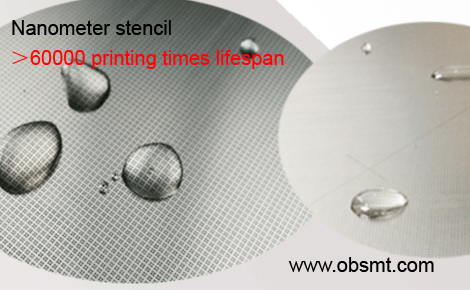

**NEW 3D nanotechnology steel stencil —-3D Nanometer STENCIL

super hydrophobicity, good tin effect, reduce time cost

Features:

1.Improve solder paste demoulding and effectively prevent solder paste from adhering to the bottom of the steel mesh and the hole wall of the steel mesh.

2.Reduce costs, reduce cleaning times, save wiping paper and solvent, less downtime, better product quality.

3.Reduce burrs, make the hole wall smoother and neater, improve solder paste demoulding, effectively prevent solder paste from adhering to the bottom of the steel mesh and the hole wall of the steel mesh, and improve the one-time through rate.

4.to solve all kinds of bad printing conditions, such as bridging, less tin, tin beads, tin uneven.

5.The nanotechnology micro-ion mask with high precision truly conforms to the national industrial policy of low energy consumption, high efficiency and green environmental protection, and meets the development direction of high precision and fine industry.

NEW Nanometer PCB stencil

For printing, now have

/Manual type /

OBSMT manual SMT stencil printing

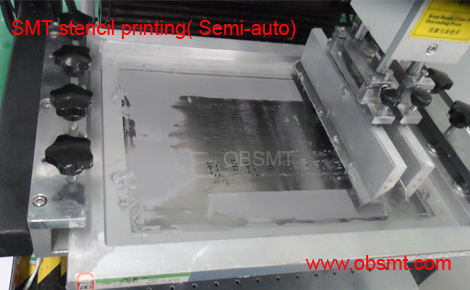

/Semi-auto type/

OBSMT semi-auto SMT stencil printing

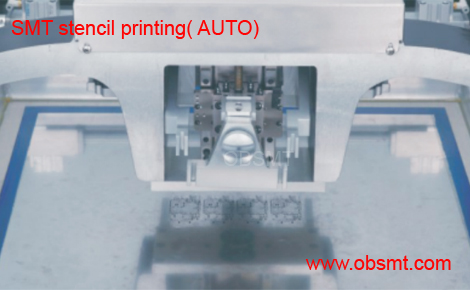

/AUTO type/

Auto SMT pcb printer