- Welcome to OUBEL !

- +86 755 2954 6287

- sales@obsmt.com

Which reason may cause semi-auto DIP soldering machine with solder point bridging defect ?

OBSMT PCB CONVEYOR SYSTEM

December 6, 2018

JUKI RS-R1 PICK AND PLACE MACHINE

July 31, 2019Which reason may cause semi-auto DIP soldering machine with solder point bridging defect ?

OB-S310 Semi-auto DIP soldering machine is most suitable for the small batch DIP PCBA welding.

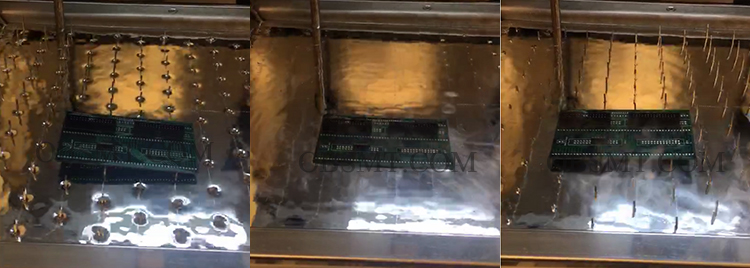

With a manual flux sprayer as a group. Working steps: manual flux sprayer– DIP welding.

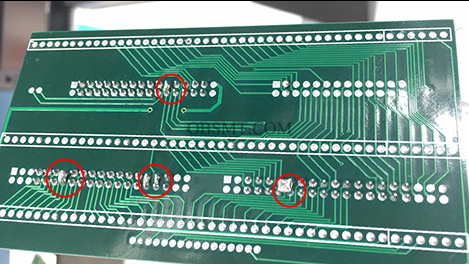

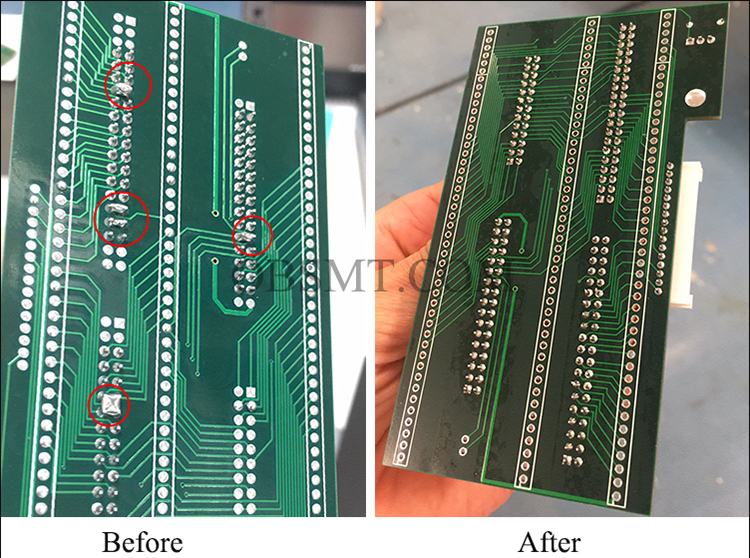

Client first time use it , will meet the welding point bridging defect problem ,like below picture:

OBSMT-S310 Semi-auto soldering machine

Cause this problem ,maybe because as following points, we will need to check one by one :

1.solder flux didn’t sprayer average,not enough.

Need enough flux sprayer,wettability should be better. If still not ok, then you will need to consider to change a solder flux to try.

Less flux will cause welding points together; More flux will cause fried tin!

2.Preheating time is not enough

0-30s preheating time adjustable , generally 20s. Before welding, the PCB can stay onto the top of the solder surface to absorb the heat. When test, you can longer it to test ,then get a better welding result.

OBSMT OB-S310 Semi-auto soldering machine

3.Heating Temperature didn’t reach the melt point!

OB-S310 semi-auto DIP soldering machine and OB-S310A manual selective soldering pot ,the temperature test precise won’t as high as the Automatic wave soldering machine. Solder bar melt point is 220℃, when P.V value is 220℃, maybe the solder tank not the 220℃, but 200℃ or 180℃. Then you will set the S.V temp to 240℃-260℃,let the solder can melt enough and can get a good welding result.

OBSMT OB-S310 Semi-auto soldering machine

Temperature is not high enough, then the needle platform will also stick some solid solder.

4.Welding angle isn’t reasonable.

OB-S310 semi-auto DIP soldering machine is with 2 welding mold , one is Straight Up and Down ; Another is with angle welding (most for PCBA welding)

This angle is adjustable , most suitable is with 45°welding. You can test and find a suitable way to get a better welding result.

OBSMT OB-S310 Semi-auto soldering machine

5.Solder pot didn’t put enough solder bar.

OB-S310 semi-auto DIP soldering machine solder capacity is 80KGS. When test , you can check the needle platform go down and the solder surface can totally flood the top side of the needle, then OK.

Less solder will cause empty burn and some points less solder.

OBSMT OB-S310 Semi-auto soldering machine

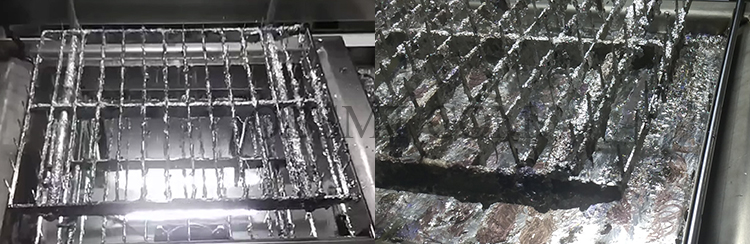

6.Solder surface with solder dross.

After several times welding, don’t forget press the “SCRAPER” button, let the scrape clean the solder surface solder dross automatically.

OBSMT OB-S310 Semi-auto soldering machine

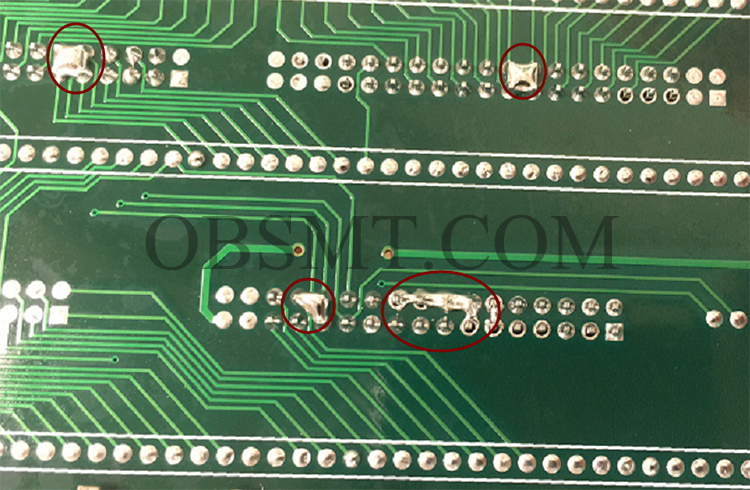

After Adjust , welding result is :

OBSMT OB-S310 soldering result

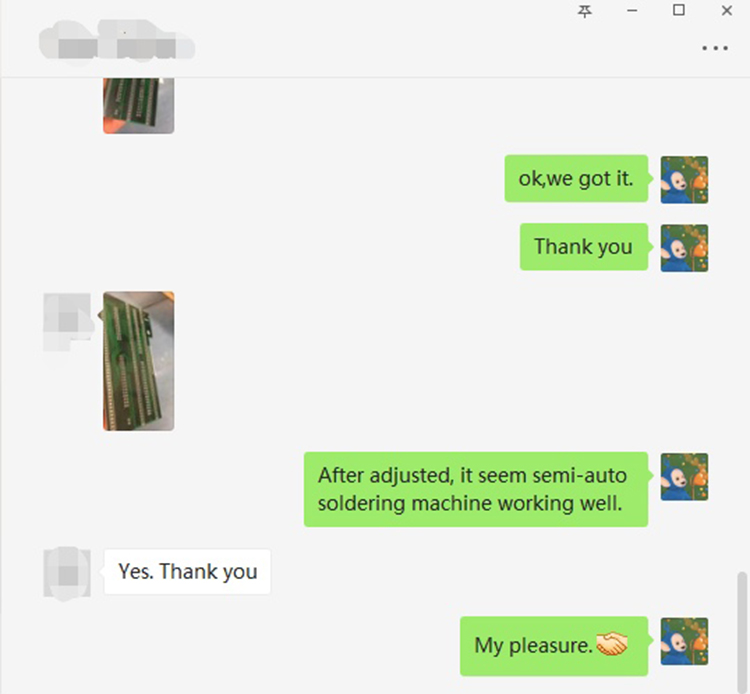

Clients feedback:

OBSMT OB-S310 Clients feedback

Any after sales problem , please feel free to contact : Info@obsmt.com