- Welcome to OUBEL !

- +86 755 2954 6287

- sales@obsmt.com

PCB Vertical Curing Oven

Shop

Hand push PCB V cutter machine

May 3, 2018

4 head economic LED mounter

May 7, 2018PCB Vertical Curing Oven

Model: OB-LS300

Brand: OUBEL

Delivery Time: 45-60 working days

PCB Vertical curing oven

For baking PCB glue , save time, save space!

The in-line vertical curing oven has the characteristics of well-knit structure,less area occupation,high productive efficiency and low energy consumption,which greatly improves the utilization rate of the factory,and is a new trend of development of the oven in the future.

PCB Vertical Curing Oven

Features:

1.Very good thermal efficiency.can be fully qualified for the product heating and cuting of various specifications,to ensure the perfect curing quality.

2.In-line automated production,save labor cost.

3.Cycle time is adjustable.Suitable fpr varoius curing process.

4.Reinforce thermal insulation structure,the surface temperature is higher about 10℃ than the room temp,to reduce the influence of the working environment.

5.Six-zone heating,flexible for setting.

6.Vertical lifting structure,save space greatly,improve the utilization rate of factory.

7.Optional nitrogen system.

Specifications:

| Model | OB-LS300 | OB-LS400 | ||||||

| Dimensions | 1980*1750*2250mm | 2180*1850*2250mm | ||||||

| Min PCB size | 90*90mm | |||||||

| Max PCB size | 300*350mm | 400*400mm | ||||||

| PCB stacking spacing | 25.4mm | |||||||

| PCB Capacity | 70pcs | |||||||

| Conveyor height | 900±20mm | |||||||

| Cycle time | 10s | |||||||

| Direction | L-R or R-L | |||||||

| Guide rail parallelism | <±0.8mm | |||||||

| Guide rail adjustment | Electric/Manual | |||||||

| Temperature range | Room temperature~200℃ | |||||||

| Temperature control mode | PID closed-loop control + SSR drive | |||||||

| Temperature accuracy | ±1℃ | |||||||

| Heating zone number | 6 | |||||||

| Heating up time | <30Min | |||||||

| Blower speed | Variable speed control | |||||||

| Powe | 3P AC 380V,50/60HZ | |||||||

| Total power | 60KW | 65KW | ||||||

| Normal working consumption | 4~6KW | 6~8KW | ||||||

| SMEMA port | In/Out | |||||||

| UPS | Standard | |||||||

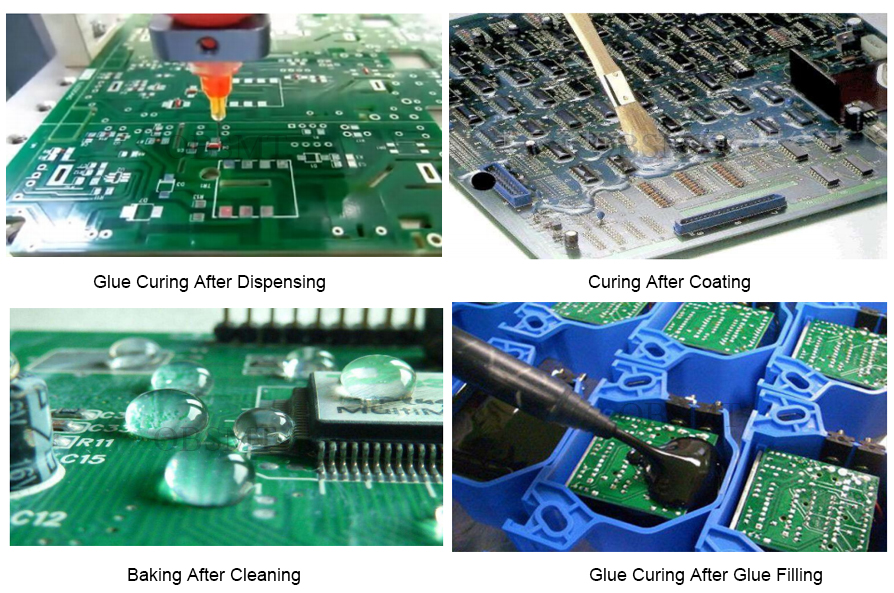

Applications:

A

A Application:

Application:

Leave message