- Welcome to OUBEL !

- +86 755 2954 6287

- sales@obsmt.com

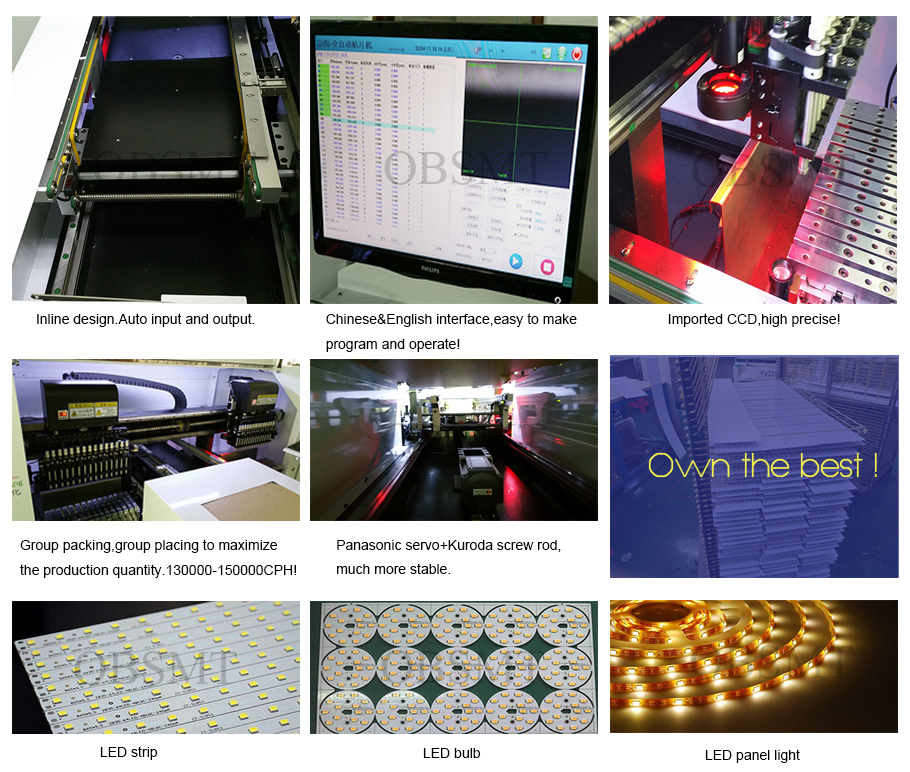

LED high speed pick and place machine

Shop

SMT tray storage cart

December 28, 2017

Manual PCB lead cutter

January 2, 2018LED high speed pick and place machine

Model: OB-G13/R3

Brand: OUBEL

Delivery Time: 15-30 working days

LED high speed pick and place machine , 100000-120000CPH , group picking and group placing; 30nozzles. Special for the LED tube ,LED strip large quantity production

High speed LED pick and place machine

OB-R3:

30 feeders SMT mounter for 1.2M/1.5M LED tube. Highest speed is up to 120000CPH.Fastest , most stable. highest cost effective!!!

Features:

1.In-line operation.

2.Panasonic servo +Kuroda screw rod,higher precise!

3.Group packing ang group placing principle,the production quantity can up to 120000-150000CPH.Fastest!

4.With 5 sets imported camera,ensure thr higher mouting precision.

5.Original nozzle pitch can be adjusted freely,nozzle angle can rotate 360°.

6.Suitable for all kinds of LED product mounting. Especially for LED tube,LED soft light.

7.Each head is controlled by independent vacuum pump.

Specifications:

| Group picking , group mounting; A/B arms can control independently. | |

| A/B arms with 15 noozles each, CCD camara mark fixture. | |

| Production qty : 110000-120000 points/hour (30 nozzles working at the same time) | |

| Guide rail driving : max. length 1.2M. | |

| Mounting height : 13mm. | |

| Max. PCB height : <3KG (include chips) | |

| PCB twist: <1mm. | |

| Chips pitch: 2mm. | |

| Conveyor: Max. speed >300mm/s | |

| Conveyor method: in line driving. | |

| Conveyor way: Front—Back or Back –front (optional) | |

| Fixture method: Optics. | |

| Air supply:>5.0KG/ CM2 | |

| Air comsuption: <80PSI(0.5Mpa) /min | |

| Specificaitons | |

| Dimensions: 2700(L)*1700(W)*1400(H) Weight : Approx.1700KGS. | |

| PCB size : <1200MM(L)*250MM(W) Thickness: 0.5mm-5mm. Fixture method: Adjustable pneumatic fasten. | |

| Operation system: Windows XP Input devices: Keyboard mounth Output device:LCD display. | |

| Chips : up 1206, 2835,3014,3528,LED tape chips. | |

| Mounting precise: ± 0.02mm Chip. | |

| Feeder qty : 30pcs.(8mm feeder) | |

| Power Supply:1P 380V AC 50Hz Total power : 3 kw | |

| Parts list | |

| X.Y aixs driving method: X,Y,Z aixs servo motor. | |

| German imported camera : industry special | |

| 2 million pixels CCD + Lense (one set),used in the MARK ficture. | |

| 2 million pixels CCD + Lense (four sets),used in the adjustment of the feeders and nozzles. | |

| Industry special computer. | |

| Moving controlling module : development by SY. | |

| Imported pneumatic elements from Japan. | |

| Left/right side holding casting by total. | |

| Bean: casting moulding by total. | |

| Motor: Panasonic | |

| pneumatic elements: Airtac. | |

| Vacuum Pump : imported from Japan. | |

| Electric controlling part: develop by SY. | |

| Sensor: Japan Omron. | |

| Maintenance tool one set. | |

| Operation environment: 25℃±2℃ |

Leave message